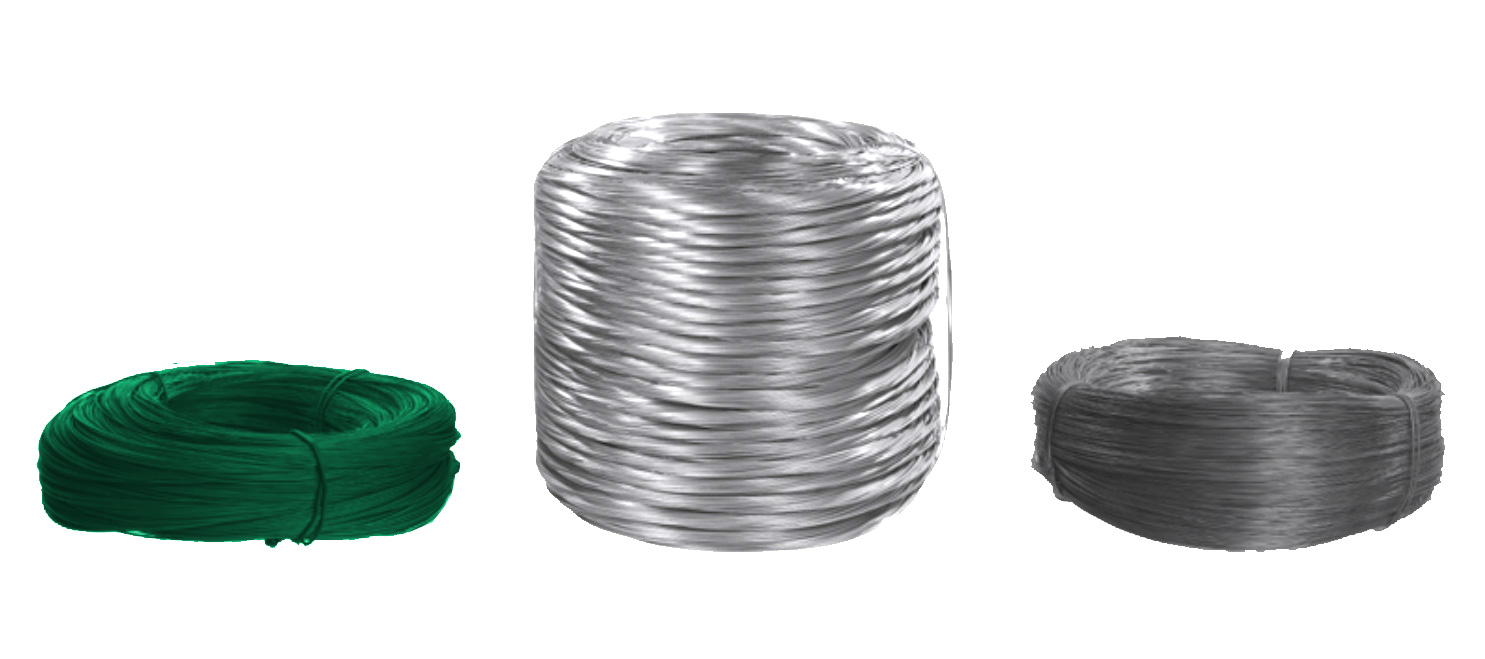

Low carbon wires are highly used in construction, agriculture and different industries and it is globally considered as an important and strategic product. These wires are produced in various shapes and sizes and their chemical components and mechanical features are completely relevant to the iron bar from which they are made. Fard Shahin industrial company produces low carbon wires St34 and St37 and these wires are produced in various shapes and sizes and their chemical components and mechanical features are completely relevant to the iron bar from which they are made. In this production unit, wires are produced in four different forms of iron, annealed, galvanized and PVC.

This type of wire is mainly used in the production of various steel meshes and nets, nails, U bolts, joists, etc. In its production, rebars of grade 6 to 8 millimeters in coil are reduced to minimum 1.2 millimeter by special wire stretching machinery, however, the most common diameter is 1.5 to 5 millimeters. The chemical properties of hard industrial wires are exactly similar to the rebar it is made from, but the mechanical features may vary depending on stretching as its elongation percentage reduces and it turns very fragile but its tensile strength increases.

Coating the surface of steel with zinc is called galvanizing. The purpose of galvanizing is to protect steel against rust and corrosion. Galvanizing is done on hard industrial wire (iron) and hot-dipped wire (annealed). In this company, galvanizing process is hot- dipped. Galvanized wires produced by Fard Shahin Industrial Company follows the latest standards and our products are classified in various covers based on our customer’s orders and are mainly used in the production of nets and meshes, steel nets, barbed wires, etc.

If necessary, hard industrial wires are placed inside anneal furnaces to a temperature of 700 to 800 degrees Celsius in vacuum condition in order to be softened and ready for use in foundation reinforcement, packaging, galvanized wires, steel meshes and nets and similar products. Upon annealing, the chemical properties of wire do not change but its mechanical properties change as its elongation increase and its tensile strength decreases.

• The size of produced wires vary from 1.2 to 5 mm (±0.05 mm possibility of fault) • The minimum size of iron wire is 1.5 mm • The standard thickness of galvanized coating is 85 g/m2 which can be increased to 220 g/m2 • The diameter of coils is 60 cm (annealed wire sizes 1.5 and 1.2 is 30 cm) • The weight of each coil is 100 kg but may be adjusted upon customer’s request. • These wires can be offered in the form of bars.

From 1.2 mm - 5 mm

g/m2 220 - g/m2 85

100 kg - 500 kg