Button bits are essential drilling tools designed for efficient cutting and penetration in various ground conditions. Made from high-quality tungsten carbide, they deliver exceptional durability, superior cutting performance, and high penetration speed, even in hard rock formations. The ROCWING 240 is a concentric overburden bit developed for challenging rock beds, featuring an enclosed design that maximizes drilling efficiency. Its unique cam sliding mechanism allows self-actuating wing bits to operate smoothly without clogging, regardless of unpredictable ground conditions. Available in multiple types, including eccentric, wing, symmetric, and hemi designs, as well as cluster hammers, these tools ensure optimal performance and reliability in demanding drilling operations.

A tricone bit is a type of drill bit with three rotating cones, each equipped with teeth or inserts, used in drilling operations to penetrate rock formations. These bits are commonly used in the oil and gas industry, mining, and water well drilling. The rolling and chipping action of the cones, combined with the drilling fluid, helps to break and remove rock from the borehole.

One of the key features of a tricone bit is its three independently rotating cones, which allow for balanced cutting and smooth operation in a wide range of formations. Each cone is equipped with a cutting structure that may include steel teeth or tungsten carbide inserts. The teeth crush and chip away at the rock as the cones roll, while the drilling string’s rotation ensures consistent engagement between the cutting surfaces and the borehole bottom. This rolling action reduces drag, improves drilling efficiency, and extends the bit’s lifespan.

Drilling fluid plays a vital role in tricone bit performance. It is pumped through internal channels within the bit to flush away rock cuttings, reduce friction, and cool the cutting structure. By keeping the borehole clean and the bit cool, drilling fluid helps maintain cutting efficiency and prevents overheating, which could damage the bit or slow drilling progress. The combination of mechanical action and fluid circulation makes tricone bits highly effective in challenging drilling conditions.

Tricone bits are available in several types to suit different applications. Mill tooth bits feature longer, widely spaced teeth ideal for softer formations, while Tungsten Carbide Insert (TCI) bits have harder, closely spaced inserts for medium to hard rock formations. These bits are widely used in oil and gas exploration, mining, water well drilling, and geothermal projects. Their versatility, durability, and ability to handle diverse geological conditions make tricone bits a preferred choice for drilling professionals worldwide.

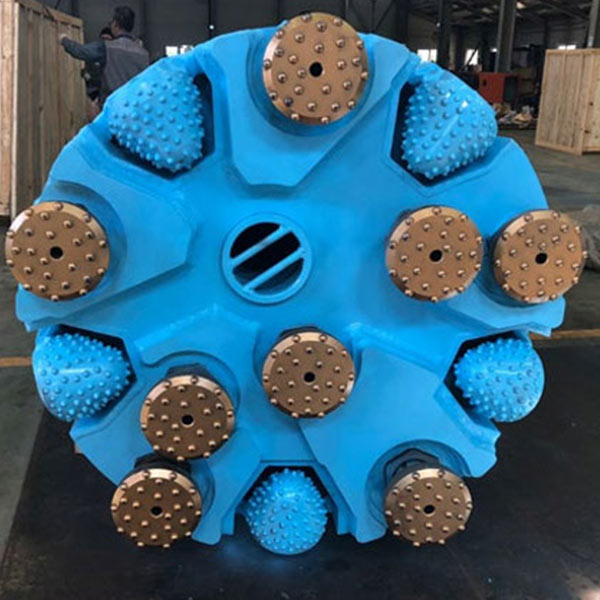

A cluster hammer is a powerful drilling tool designed for creating large-diameter boreholes in hard rock and overburden formations. It consists of multiple smaller down-the-hole (DTH) hammers mounted together in a circular arrangement, working simultaneously to break and remove rock. Cluster hammers are widely used in foundation drilling, pile installation, mining, and large-scale construction projects where strength, precision, and efficiency are critical.

One of the defining features of a cluster hammer is its multi-hammer configuration, which distributes the impact energy evenly across the drilling face. Each hammer operates independently yet in coordination with the others, delivering high-frequency impacts that efficiently fracture rock. This design ensures smooth operation, reduces vibration, and allows the drilling of exceptionally large holes that would be difficult or impossible with a single hammer.

Air or drilling fluid plays a key role in cluster hammer operation. Compressed air or fluid is directed through each hammer to clear rock cuttings from the borehole and cool the hammer components. This not only maintains drilling efficiency but also extends the service life of the hammers by preventing overheating and wear. The combination of powerful mechanical impact and effective cuttings removal makes cluster hammers highly reliable in demanding drilling environments.

Cluster hammers are available in different configurations and bit types to suit various geological conditions and project requirements. They can be equipped with different face designs, button arrangements, and carbide grades for maximum performance in both hard and mixed formations. Their ability to deliver large-diameter holes with high penetration rates makes them a preferred choice for heavy-duty foundation work, mining operations, and specialized drilling projects around the world.